20 years after founding the W.E.St. Elektronik GmbH, Mr Ulrich Walter has decided to begin his well derserved retirement and to sell the company to new owners. This step has been very carefully prepared over the last months with the new owners, namely Thomas Helpenstein and the Swedex Holding GmbH. Based on that, we would also like to announce that Thomas Helpenstein will be named managing director of W.E.St. Elektronik GmbH, effective October 1st, 2019.

The Swedex Holding GmbH has established its market presence by the Swepro group for more than 30 years, as a specialized supplier of innovative and sophisticated pneumatic solutions including industrial tools and the broadest offering of air nozzles, complemented by electrostatic solutions. The Swepro group currently employees over 100 people in 13 countries globally.

Thomas Helpenstein has made his career in developing and marketing of industrial control device. He has held positions in engineering, product management and business management with global responsibility for a wide range of industrial components used for machinery automation and functional safety for machinery.

Affiliating with a solid corporate business offers a wide range of opportunities for collaboration and to leverage each other’s competencies and resources. With this and together with Thomas Helpenstein‘s broad experience we strongly believe that the W.E.St. Elektronik GmbH is very well prepared to foster our key competencies, evolve products and technologies and expand their distribution in future.

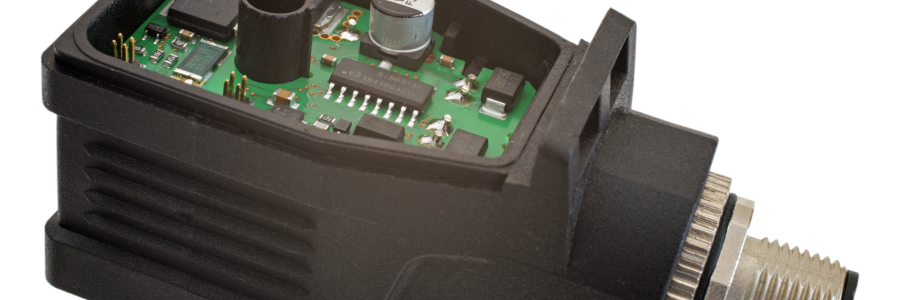

We will continue to focus on developing and expanding our offering of electronic control modules for hydraulic applications, especially complementing this offering by network based components to provide a contemporary solution for your hydraulic system with seamless integration with superior controls (PLC).

Customer loyalty and a close relationship has been and will be a key value for us. Therefore, the team and location of W.E.St. Elektronik GmbH will remain as is so that nothing changes for you! Please use the same contacts as usual and place your orders via email, fax or phone etc. as before.

Finally, we would like to thank Elke Walter and Ulrich Walter for the the last 20 years and wish all the best for their retirement!