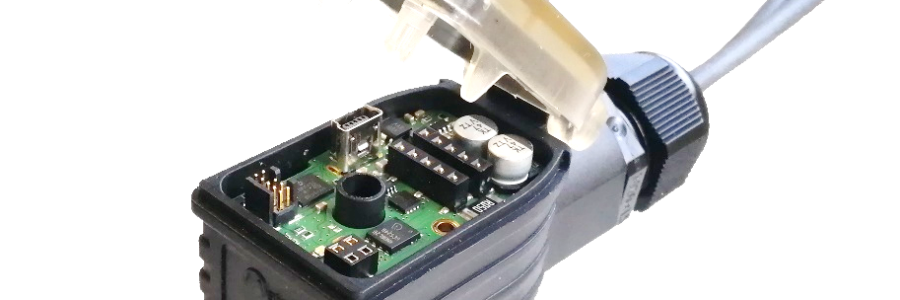

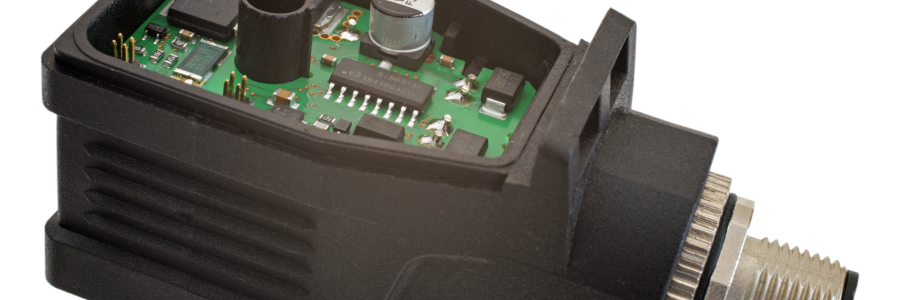

The plug amplifier family is being expanded by the Duo amplifier – a compact valve amplifier for direct installation on the solenoid coil for directional valves with two coils. The individual amplifier handles the coordination and control of both solenoid coils for smooth direction control.

The amplifier controls both magnets via one parameter set. It is no longer necessary to adjust the setpoints for two different devices using external mechanisms.

The flexible control cable makes it possible to move the connection to a more convenient location. This reduces the space required for the valve assembly. The cable length of the satellite connection for the second magnet is long enough so that there are no restrictions on the selection of the valve size.

The plug amplifier is programmed as usual with the tried and tested WEST software WPC-300, so it is not necessary to familiarize yourself with new software.